Understanding the combustibility of building materials is crucial for fire safety and compliance with building codes. This article delves into the definitions and standards that determine whether a material is combustible and explains how building codes, such as the International Building Code® (IBC®) and the International Residential Code® (IRC®), classify materials based on tests like ASTM E136 and ASTM E2652. These tests assess materials’ reactions to high heat, ensuring they meet safety criteria. The classification impacts fire safety measures and building design, making it essential to verify applicable codes and standards for each project.

What Makes a Building Material Combustible?

The design and construction of the built environment is regulated through enforcement of building codes and standards (‘codes’) by the authority having jurisdiction (AHJ). These codes are either based on a model code or standard, or promulgated by the individual jurisdiction. Most, if not all, of the codes include provisions for the testing of building materials and for their qualification either: (1) as a noncombustible construction material or (2) for use where the code requires noncombustible construction materials.

ASTM International (ASTM) standard ASTM E176 Standard Terminology of Fire Standards1 defines “combustible” and “combustion” as follows:

- combustible, adj – capable of undergoing combustion.

- combustion, n – a chemical process of oxidation that occurs at a rate fast enough to produce temperature rise and usually light either as a glow or flame.

These terms are also contained in the NFPA Glossary of Terms2 and ISO 13943:2023 Fire Safety – Vocabulary3 standard where the terms are similar to, if not the same as, those provided by ASTM. Beyond any definitions provided by these Standards Development Organizations (SDOs), a building code may also choose to define combustible or noncombustible.

Visible flaming accompanied by the release of heat are the most common manifestation of combustion. However, combustion may also occur without visible flaming, which is commonly evidenced by the release of heat and combustion products such as smoke, char, and vapors. Smoldering combustion is an example where visible flame is not present but combustion processes such as heat release and others are occurring.

Building Material Combustibility: Standards and Fire Safety Testing

When applied to materials, the “combustibility” of a material is assessed by how it behaves or reacts upon exposure to heat or flame. A material’s response to heat or flame is evaluated and characterized by testing standards. The test standards use specific, defined, and controlled exposure conditions and may also include performance classification, rating, or pass/fail criteria. In addition, materials are often required to be tested in the form or physical state intended for use.

Although the broader concept of combustibility is more than whether or not a material is capable of undergoing combustion, it is a common approach among model building codes to classify building materials and assemblies as “noncombustible” or “combustible.” This binary classification is one of the basic foundational elements of fire safety from which the codes derive fire safety through additional interrelated requirements that are likely to include fire tests of materials and assemblies.

Combustibility in Building Codes: Understanding ASTM E136

International Building Code® (IBC®) and the International Residential Code® (IRC®) are the most commonly adopted model building codes in the United States. Both the IBC and IRC reference ASTM E1364 regarding the general combustibility of building materials – that is, to qualify building materials for use as noncombustible materials under the IBC and IRC.

The IBC and IRC take different approaches to the subject of noncombustible materials. The 2000 through 2024 editions of the IRC use a definition in Section R202 for the term noncombustible material and the definitions include reference to passing ASTM E136. The IRC, in Section G2403 contains a different definition for noncombustible material that is specific to IRC Chapter 24 and includes the criteria of acceptance; criteria that is consistent with the criteria stated in the ASTM E136 test method. By comparison, IBC (2000 through 2024 Editions) prescribes provisions for testing materials to qualify them for use as a “noncombustible material” where such materials are required by IBC. The IBC provisions in Section 703.3.1 prescribes that materials required to be noncombustible are tested and pass ASTM E136. Section 703.3.1 contains an exception for materials having a structural base that is noncombustible based on testing to ASTM E136 and a surfacing that is both a maximum thickness of 0.125 inch and provides a flame spread index of 50 or less when tested to ASTM E845. Later editions of the IBC added reference to ASTM E26526, using the acceptance criteria of ASTM E136, as an alternate testing method to qualify materials for use as noncombustible. Beginning with the 2011 edition, ASTM E136 included a Test Option B that uses the E2652 test apparatus.

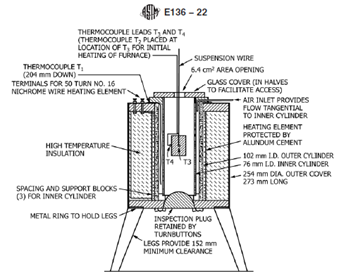

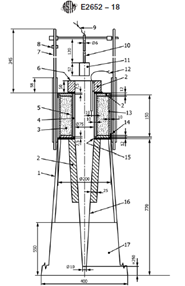

The test apparatus of ASTM E136 is a vertical tube furnace (Figure 1) where ASTM E2652 is also a vertical furnace but of conical design (Figure 2). The exposure condition for both tests is simply extremely high heat (not flame), stabilized at a temperature of 750°C before the test specimen is inserted into the test furnace. The ASTM E136 test duration is 30 minutes, and the procedure requires the test to be conducted on each of four (4) individual test specimens.

Figure 1. Used with permission of ASTM International from Standard Test Method for Assessing Combustibility of Materials Using a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750°C, Subcommittee E05.23, 2022; permission conveyed through Copyright Clearance Center, Inc

Figure 2. Used with permission of ASTM International from Standard Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750 °C, Subcommittee E05.23, 2024; permission conveyed through Copyright Clearance Center, Inc.

The criteria for passing the ASTM E136 test combines observations of visual flaming from the test specimen, weight-loss of the test specimen, and any increase in the furnace temperature above the stabilized furnace temperature measured at two locations associated with the test specimen: thermocouple T3 located at the geometric center of the test specimen and thermocouple T4 located on the surface of the test specimen. A material passes the test when at least three (3) of the four (4) test specimens meet the following Individual Test Specimen Criteria as observed and recorded throughout the duration of each individual test:

| Test Specimen Weight Loss | Flaming from Test Specimen | Recorded Temperature Increase | |

| Test Specimen Center (T3) | Test Specimen Surface (T4) | ||

| </= 50% | None after 30 sec | < 30°C | < 30°C |

| > 50% | Flaming not permitted | No increase | No increase |

Considerations for Other Building Codes

It is important to remember that other building codes adopted by other jurisdictions will reference other fire test methods within their respective requirements for building design and building materials, including requirements for the qualification of building materials as “noncombustible.” It is also important to remember that how other building codes approach fire safety will influence how those fire test methods are referenced and used by the code. Depending on the regulating code, those requirements could prove similar to those in the IBC, IRC, and ASTM E136 or very different, therefore, always verify the applicable codes, regulations, and applicable testing and performance requirements for projects.

Footnotes

- ASTM E176-24 Standard Terminology of Fire Standards, ASTM International, West Conshohocken, PA. ↩︎

- NFPA Glossary of Terms, 2021 Edition (Updated as of March 30, 2021), National Fire Protection Association, Quincy, MA. ↩︎

- ISO 13943:2023 Fire Safety – Vocabulary, International Organization for Standardization, Switzerland ↩︎

- Both the 2024 IBC and IRC reference ASTM E136-22 Standard Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750°C ↩︎

- 2024 IBC references ASTM E84-21a Standard Test Methods for Surface Burning Characteristics of Building Materials ↩︎

- ASTM E2652 Standard Test Method for Assessing Combustibility of Materials Using a Tube Furnace with a Cone-shaped Airflow Stabilizer, at 750°C ↩︎